Automated, Vibratory Feeding System Ideal for Auto Assembly Lines

TM Robotics, along with EPF, has presented the SUPATA system to replace rigid and unreliable vibratory feeders.

The system is designed to handle smaller and smaller batches with frequent production changes, to be ready for new products, to create assembly lines without having to intervene with structural works, and to manage it all with a single HMI interface.

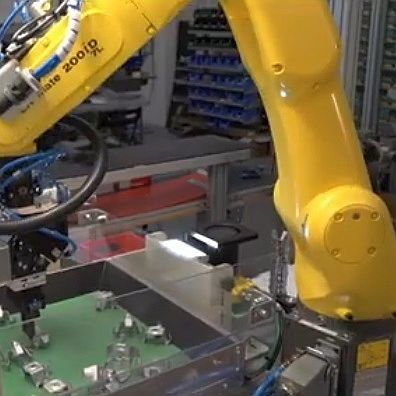

The Supata Flexifeeder automated feeding system -- developed and manufactured by EPF Elettrotecnica -- overcomes the limitations of more traditional vibratory feeders. The solution consists of a feeding system, a vision system, a human-machine interface (HMI) control system and an integrated robot from Shibaura Machine.

VIDEO: Smart Feeder EPF Supata®

The flexible feeding system features advanced artificial intelligence (AI) vision that significantly reduces errors while boosting productivity by 17 to 20 per cent. With unparalleled precision and speed, Supata is ideal for automotive, medical and electronics production lines.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::